You can tell a lot about a farmer by how they talk about their grain setup. Some brag about how fast they can dump a truck, others about how gentle their system is on seed beans. But sooner or later, every farmer faces the same question:

Do you go with a grain leg or a chain loop?

I’ve run both, climbed both, and fixed both in the rain. They each have their place, but not on every farm.

The Grain Leg – The Big Vertical Muscle

If you’re building a brand-new site, the leg is usually the first thing you picture. Tall, shiny, and powerful, it’s the heart of those big-time commercial-style operations.

A leg is simple in concept: buckets on a belt, hauling grain straight up from a pit and spitting it out at the top into spouts that feed your bins. It’s a tried-and-true system that can move serious bushels fast.

Where the Leg Shines

- Speed and capacity: Nothing moves grain vertically like a leg. Once it’s running, trucks flow through fast.

- Built for big, centralized layouts: When your bins sit in a tight cluster, one leg can feed them all.

- Longevity: A well-built leg can last decades with routine maintenance.

- Clean transfer: Less chance for leftover grain mixing between crops compared to enclosed systems.

Where the Leg Bites

- Upfront cost: The leg itself isn’t the expensive part; it’s the concrete, the deep pit, and the tower structure. That can double or triple the bill.

- Safety and maintenance: Climbing 80-100 feet to grease bearings or check belts is not a fun job.

- Limited flexibility: If you ever expand in a new direction, you’re probably adding another leg or major rebuild.

- Grain damage risk: The fast centrifugal discharge can create fines if the leg is over-speed or poorly maintained.

Best Fit

If you’re starting fresh, especially with over 250,000 bushels or more in a tight footprint, a leg can make sense. You’ll pay more upfront, but it’ll handle huge volume quickly and run for years.

The Real World Comparison

If you’re upgrading an old site, the leg’s cost and layout limitations can be painful. By the time you add a new pit and tower, you might as well have built a new bin yard.

The Chain Loop – The Quiet Workhorse

The loop is the opposite personality: no towers, no climbing, no concrete jungle. It’s a closed-tube system with a chain and paddles that pull grain through a continuous loop, usually running under the bin line.

It’s simple, quiet, and easy to expand.

Where the Loop Shines

- Lower installed cost (especially for retrofits): You can often use your existing bins and concrete. Just trench a path for the loop and tie everything together.

- Gentle on grain: The en-masse drag style moves grain rather than flings it, which is ideal for seed beans, specialty crops, or premium corn.

- Easy expansion: Add bins? Extend the loop. Need a new discharge? Cut in another drop.

- Ground-level maintenance: Everything is serviceable without a 100-foot climb.

- Blending and drying benefits: Because you can move grain in a circuit, blending moist and dry grain is easier and can save on dryer fuel.

Where the Loop Falls Short

- Limited vertical lift: It doesn’t like steep climbs. If your bins are much higher, you’ll need extra run length or an auxiliary leg.

- Chain wear and tensioning: More moving parts to check. Neglect the chain and you’ll be down at the worst time.

- Cleanout time: Because it’s a closed system, it takes longer to empty when switching crops.

- One-direction flow: Most loops are not reversible; design your layout carefully.

Best Fit

If you’re upgrading an existing bin site, the loop is often the smartest route. You avoid deep pits, tall towers, and you can tie bins together at ground level. For a new build, loops can still win, especially if your site is spread out or your storage grows in stages.

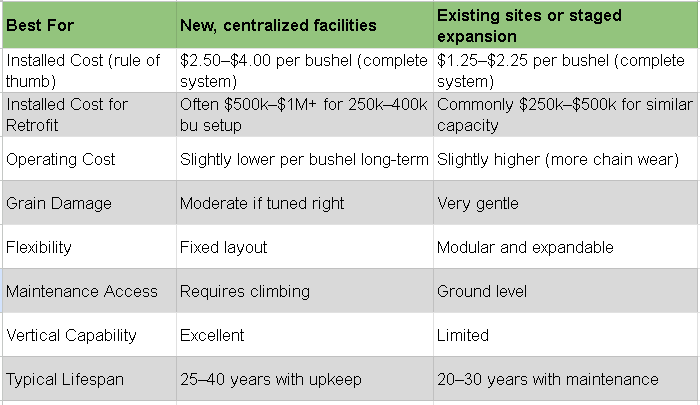

The Real-World Comparison(Numbers are based on farm builder averages and 2023–2024 install data across the Midwest.)

Rule of Thumb for Choosing

Here’s how I simplify it when neighbors ask:

- If you’re pouring new concrete and want a clean, centralized setup that’ll run for 30 years, go with the leg.

- If you already have bins and just want to tie them together efficiently, loop wins nearly every time.

- If you’re planning phased expansion, the loop gives you flexibility without doubling your dirt work.

- If you run seed beans or food-grade crops, gentle handling pays for itself.

In short:

The leg is an investment in throughput.

The loop is an investment in flexibility.

Both will move your grain just fine; the real difference is how much dirt and steel you want to pay for to get there.

Leave a Reply