I’ve been farming my whole life, as did my dad, my grandpa, and his dad before him. We’ve seen a lot of changes over the years, from walking beans to using GPS. But let’s be honest, nothing beats a good, old-fashioned harvest. The long days, the dust, the satisfaction of seeing a full truck heading to the bin. What’s not so great? Trying to find a reliable grain cart operator who can handle the long hours and the pressure.

Well, folks, things are changing faster than a combine can fill a cart. Grain cart automation isn’t some pie-in-the-sky idea anymore. It’s here, and it’s getting better every season. Here’s the straight scoop on what’s new and what it means for our operations.

From Beta to the Back 40

The biggest news is that this stuff is no longer just for big-money test farms. Companies like PTx Trimble and CNH Industrial are now selling retrofit kits that you can put on your existing tractors. This isn’t about buying a whole new rig. It’s about upgrading the tractors you already own, which is a big relief for the pocketbook. Raven’s kit, for example, is available to buy and install. This “mixed fleet” approach means you can use the best technology, no matter what color your tractor is.

Smarter, Not Just Driverless

The new systems are more than just a fancy auto-steer. The latest tech is focused on making life easier for the combine operator.

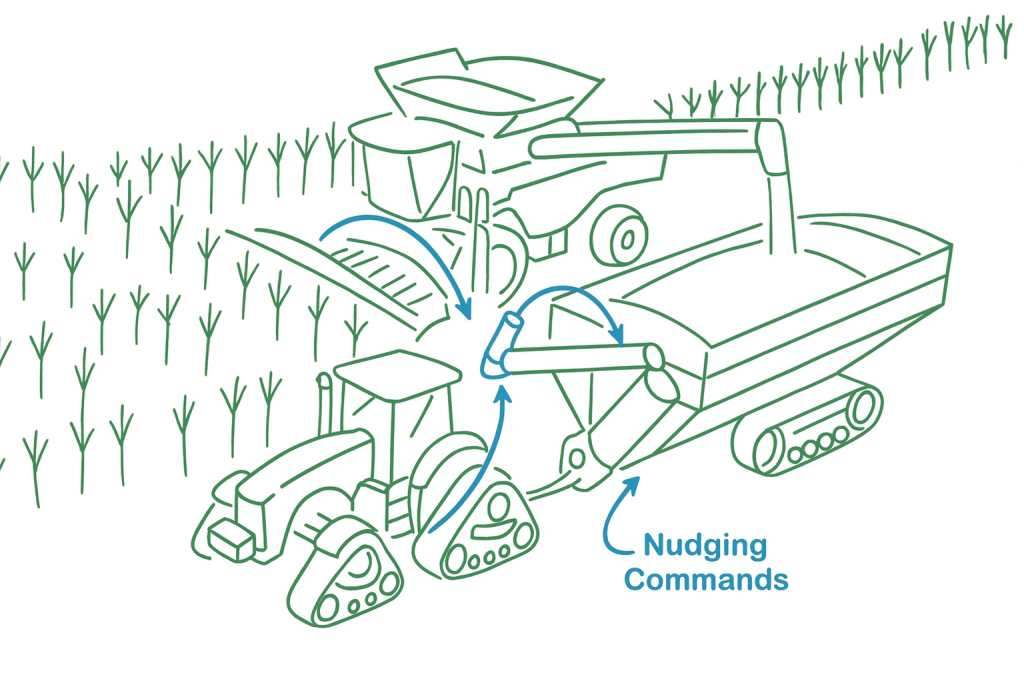

- Auto-Unload Camera: Some new systems, like one from John Deere, put a camera on the combine’s auger. This camera actually “sees” the grain cart and automatically nudges the tractor forward or back to fill it evenly. No more frantic hand signals or yelling on the radio.

- Combine Operator Takes Control: Systems like the Raven Cart Automation let the combine operator take command of the grain cart. You can make small adjustments right from your cab, ensuring a perfect fill every time. This cuts down on spillage and makes the whole process smoother.

- Multi-Machine Coordination: For bigger operations, these systems can now coordinate multiple grain carts with one combine. This is a game-changer for harvest logistics, keeping everything in sync and the combines moving.

Answering the Labor Problem

Let’s face it, finding good help is a real struggle. This is where automation really shines. The combine operator can focus on harvesting, not on constantly communicating with the grain cart driver. This reduces stress for both people and leads to a more efficient day.

These systems are designed to be intuitive, almost like a video game. Companies are selling this tech by highlighting how a less experienced operator can handle the grain cart job. This means you can get a new guy up to speed a lot faster and have confidence that the job will get done right.

It’s a “Path to Autonomy,” Not a Giant Leap

The big companies aren’t expecting us to go fully autonomous overnight. They’re calling it a “path.” You can start with these grain cart kits, and as you get more comfortable, you can add other technologies down the road. It’s a step-by-step approach that makes the whole thing feel less intimidating.

My Two Cents: The Practical Takeaways

Nobody’s saying this replaces a good conversation in the field or a shared lunch break. But this technology is a tool, just like a better combine or a newer planter. It’s a way to save time, reduce waste, and get the harvest in when the weather is right.

For a family farm like mine, where a full crew is scarce, this could mean the difference between harvesting the crop on time and leaving it to the mercy of a late-season storm. It’s an investment, for sure, but one that might just pay for itself in a few good seasons. It’s about working smarter, not just harder. My grandpa probably wouldn’t have believed it, but I bet he’d be the first one to say, “Well, if it gets the job done and saves a little sanity, what’s not to like?”

Leave a Reply